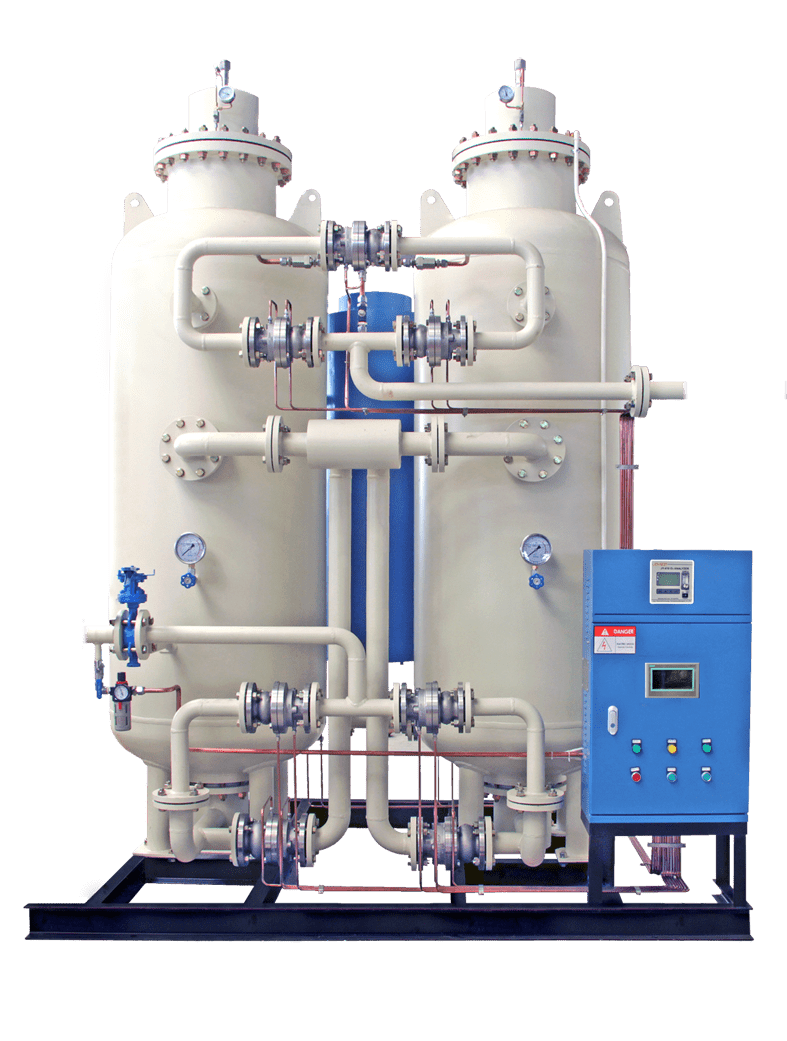

PSA Nitrogen Generator

Nitrogen flow:5~12000 m3/h(20℃,101.325kPa)

Nitrogen purity: ≥97~99.9995%(Customizable)

Excellent Energy-saving Features

Reduce Air Usage Cost

Advanced process flow directly reduces compressed air consumption

The energy-saving CMS nitrogen generator provided by CoolAir adopts unequal pressure equalization process (RL-VI flow, patent certificate no.364126).

This process improves desorption tower nitrogen purity and reduces CMS oxygen pre-adsorption in the desorption tower and increases CMS utilization ratio, i.e,increases carbon molecular sieve nitrogen production rate. RL-VI process not only improves nitrogen recycle rate and carbon molecular sieve utilization ratio, but also changes the history that no ppm class high purity nitrogen can be produced by PSA technology.Key Features

The higher nitrogen purity,the more energy-saving

Nitrogen Generator Process:

Nitrogen Generator Process:Clean compressed air flows inter tower A, when passing through the carbon molecular sieve, oxygen, carbon dioxide,water and other contaminants are adsorbed, allowing nitrogen flows out as product gas CMS in tower A becomes saturated as time goes by. Then tower A stops adsorption and compressed air enters tower B to adsorb oxygen and produce nitrogen. Meanwhile, CMS in tower A begins regeneration, Two towers make alternate adsorption and regeneration to separate nitrogen from air and continuously produce nitrogen.

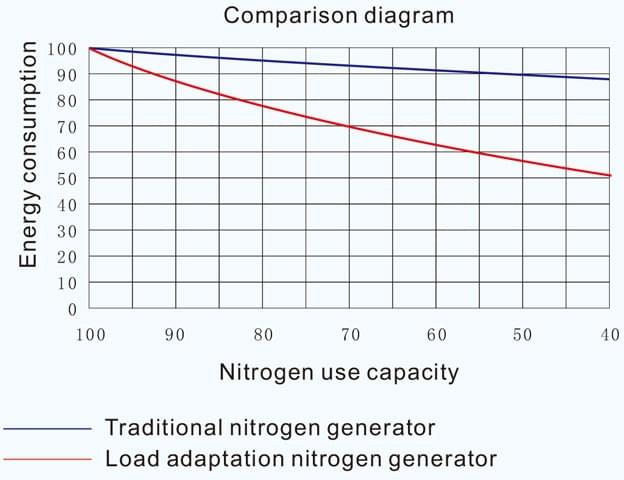

Advanced load adaptation technology further saves energy

Load adaptation is a new concept developed by CoolAir in its PSA system R&D experiences. It is the achievement of CoolAir technical engineers based on many years simulation experiments and repeating demonstrations. Under the circumstance of air consumption decrease, load adaptation realizes energy consumption reduction by prolonging adsorbing circulation period and realizes extra energy-saving in typical load range.

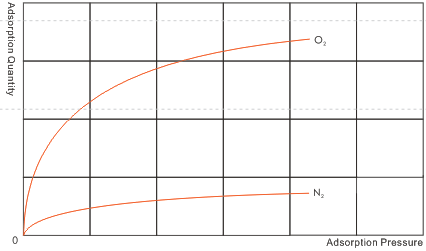

The most reliable air cleaning process ensures adsorbing efficiency and lifetime of molecular sieve

As shown on the diagram above,carbon molecular sieve has obvious adsorption differences to oxygen and nitrogen. There are many tiny holes inside the carbon molecular sieve.Under certain pressure,the tiny holes have different adsorption capacity to oxygen and nitrogen.When air pressure increases,carbon molecular sieve adsorbs oxygen and produces nitrogen,when air pressure drops to normal condition,carbon molecular sieve desorbs oxygen and regenerates itself.Two towers are generally provided,when one absorbs oxygen and produces nitrogen,the other desorbs oxygen and makes regeneration.This alternate process constantly produces nitrogen.

Technical Advantages & Specific

What's different to others

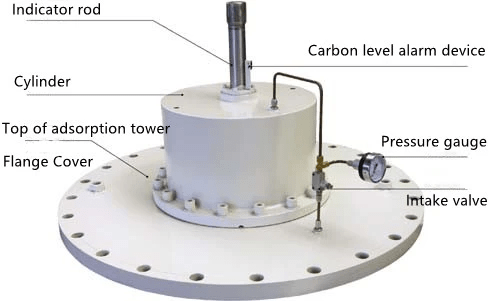

Air tank ensures stable system air consumption

The function of air tank assembly is to ensure stable system air consumption, to prevent momentary fast air flow as oxygen and nitrogen separation system switches work.Failure to do so will greatly deteriorate air cleaning effort.This assembly improves the quality of the compressed air that entering adsorption tower and prolongs carbon molecular sieve life time.This assembly contains air tank,safety valve,check valve,ball valve,pressure meter,etc.

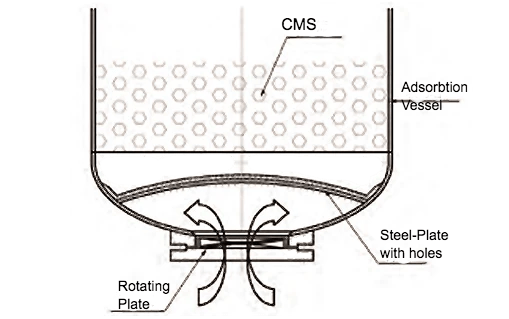

Inlet Air Turbo-flow

Further strengthen the utilization rate of molecular sieve, improve the structural design of adsorption tower with unique equipment performance, effectively change the speed and direction of internal gas flow, reduce the appearance of dead space in the tower, and further improve the utilization rate of molecular sieve; At the same time, avoid the impact of high-pressure gas flow on molecular sieve, reduce the pulverization of molecular sieve, which is conducive to extending the service life of molecular sieve, improving the adsorption performance of molecular sieve, and reducing energy consumption.

The national patent absorption tower

The unique structural design can change the speed and direction of internal airflow, reduce the dead space in the tower, and improve the utilization rate of molecular sieve, which is conducive to extend the service life of molecular sieve, improve the adsorption performance of molecular sieve, and reduce energy consumption.

PSA Oxygen Generator

PSA H2 EXTRACTION

rare gas, CO, CO2, Hydrogen

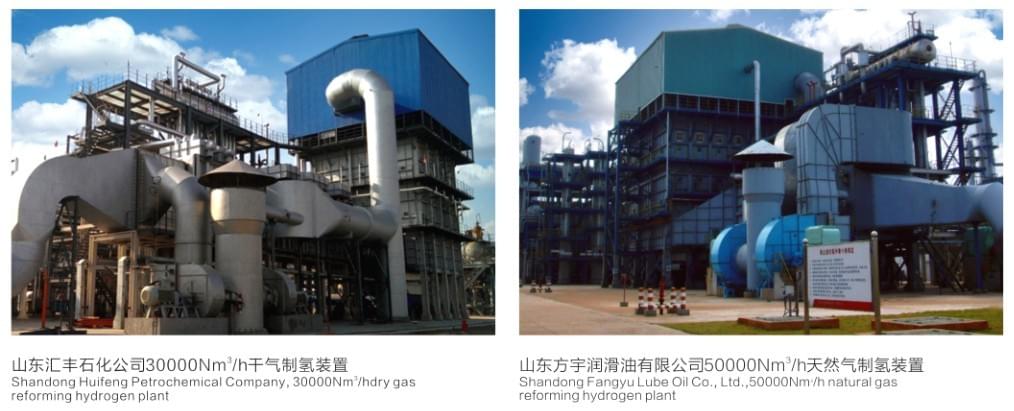

Hydrogen reforming plant

from Natural gas steam conversion

Capacity: 50 - 20 x 10000Nm3/h

Raw material: Natural gas, LPG, methane, propane, coking dry gas...

Contact us

send us message

mail us

Skype

visit us

phone